Featured products

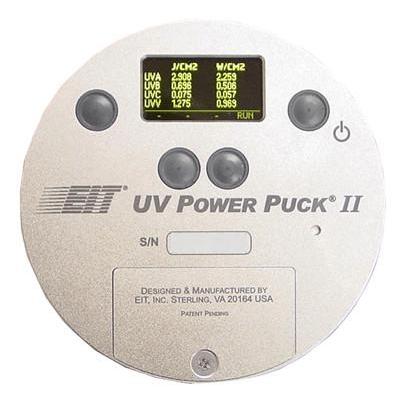

Power Puck II UV Radiometer

from $5,326.99

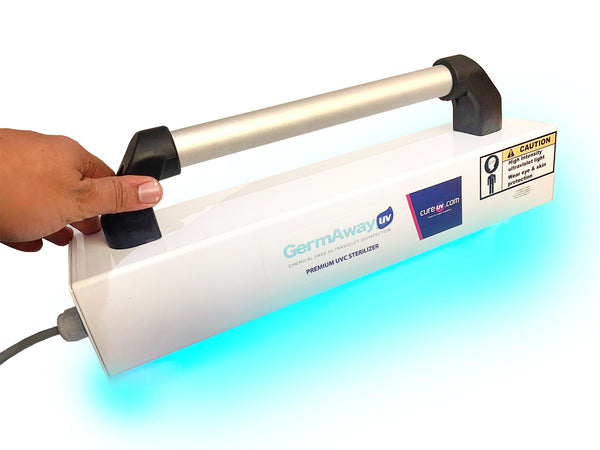

GermAwayUV Ultraviolet Ambulance Disinfection System

from $599.99

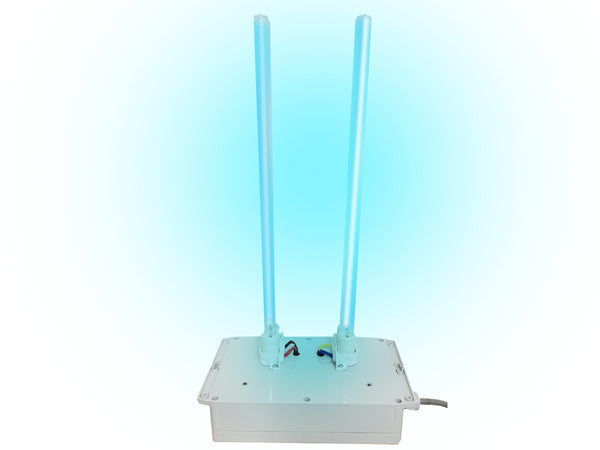

Heavy Duty Dual Bulb 72 Watt HVAC UV Air Purifier

from $249.99

GermAwayUV HVAC Coil Scrubber 36 or 72 Watts

from $249.99

Small Handheld UVC Surface Sanitizer Wand

$19.99 $59.99